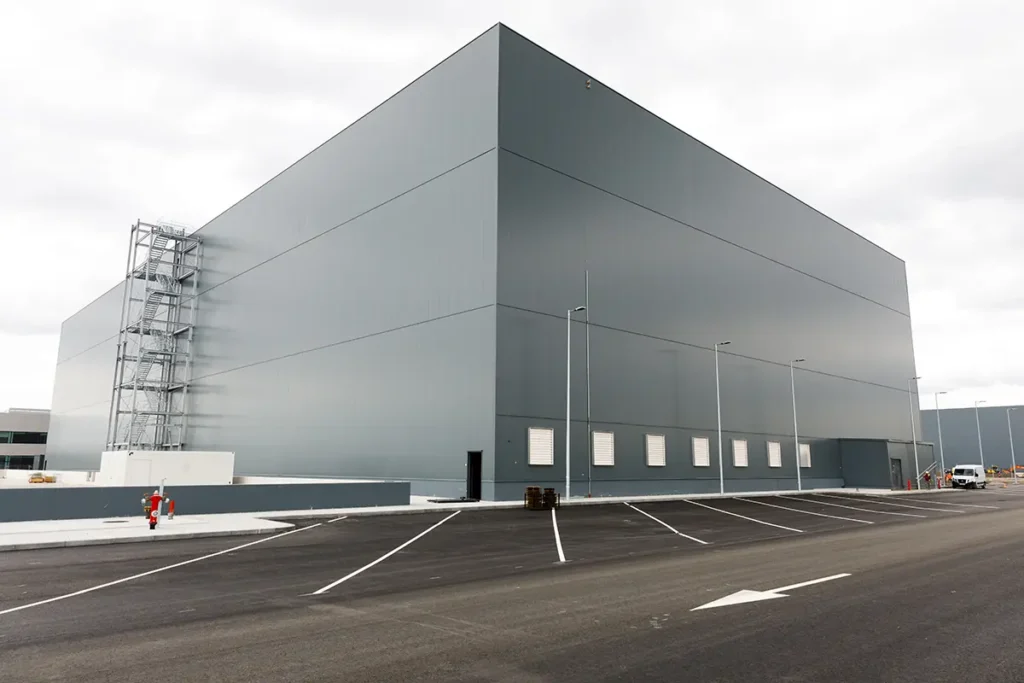

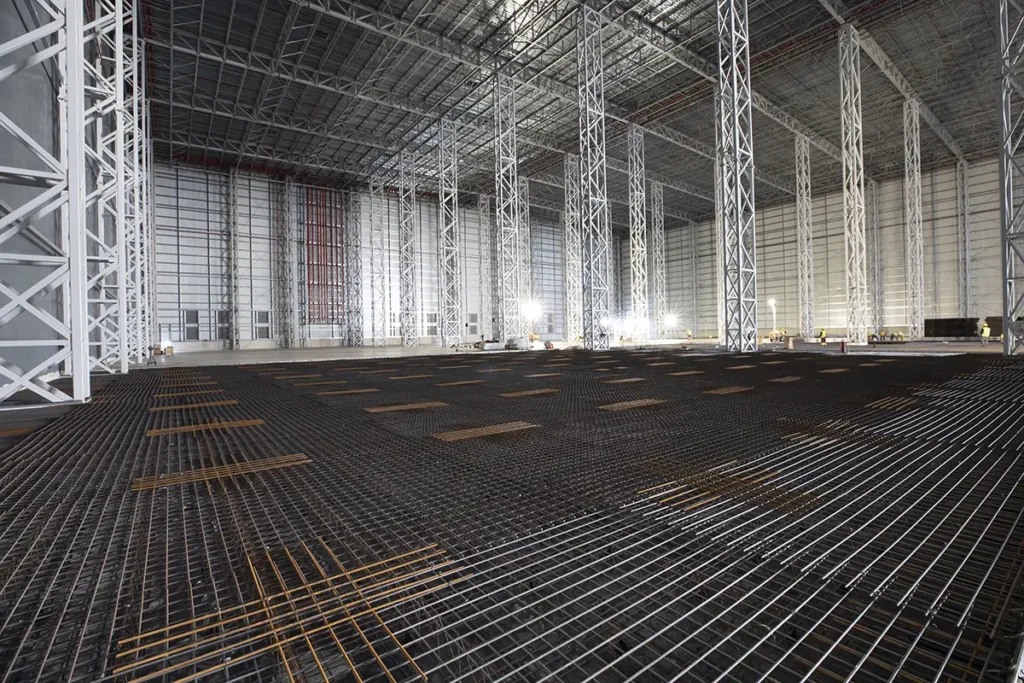

Silos are single-storey, high-rise buildings that support huge automated structures to move goods horizontally and vertically at high speed. In this case, the silos reach 34 metres in height, equivalent to an 11-storey building. In order to support the enormous structure of racks and robots vertically, it is necessary to be close to perfection in two aspects: the regularity of the floor (horizontality and flatness) and the resistance to the loads, as it is only one floor that supports the building.

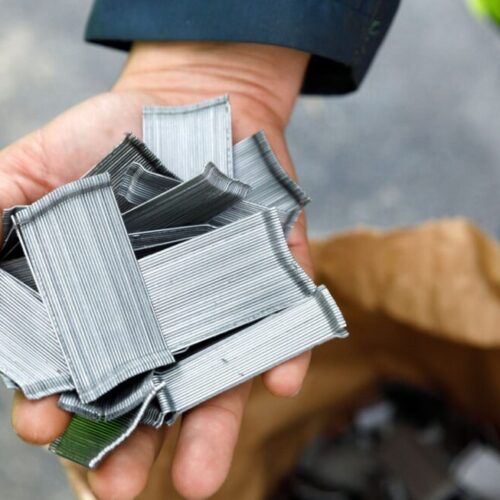

Both the main hall and the silos have a double steel skeleton – double mesh – but the latter also accompany the concrete mix with millions of strategically distributed steel fibres that increase resistance to the loads. This is a fact about the largest silo: it carries 550 tonnes of mesh and 220 tonnes of metallic fibres, which add up to 770,000 kilograms of steel to strengthen the pavement. That metal would make a dozen Leopard 2 tanks. Just the fibres of the main silo, put in a row, would make a full circle around the earth. To get performance from the fibres, a very detailed study of densities, distribution, orientation, etc. has to be carried out. As Juan Carlos Arroyo, PhD in Architecture and Structural Engineering, explains, ‘the main thing is the reinforcement, and the fibres only if they are used with rigour; they could be useless or even lead to a false security by neglecting the main steel structure, which must be double mesh’.